Automated Sample preparation & liquid handling

The problem

As biologics and gene therapies move through development, they commonly become more viscous and harder to handle. Whether that’s because of the high concentrations a biologic typically requires, or the presence of the complex reagents used to formulate proteins, viral vectors or nanoparticles, liquid transfers become more inaccurate and imprecise.

The right tool for the job

Big Kahuna and Junior are configurable automation platforms that can be configured as automated sample preparation systems to prepare biologics and gene therapy formulations, test those formulations, and integrate any analytical results. Because of the highly variable nature of some biologics and gene therapy reagents, we have two options for automated liquid handling on the Big Kahuna and Junior platforms. This includes traditional air displacement tips (ADT) for most solutions, and for transfer of the more sticky stuff, we recommend using positive displacement tips (PDTs).

What’s possible

Six-tip air displacement tips (ADT) dispense

For less viscous solutions, Big Kahuna and Junior use the six-tip liquid transfer arm for automated sample preparation. It uses standard pipette tips from 50 -1000 µL capacity. The pitch is adjustable between 9 mm for standard plates and 20 mm, which is handy for larger vials. This capability allows for sample or plate reformatting. The use of syringe pumps for every tip means each can pick up different volumes if that’s what needs to happen. The tip pick up is also individually controlled so if your workflow needs to use just a few positions it can handle that too.

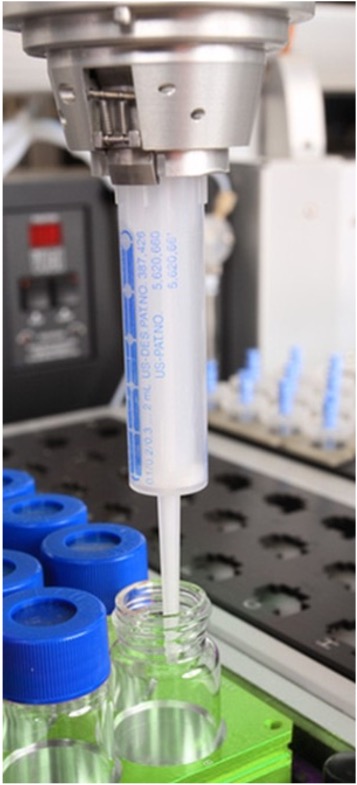

Positive displacement tips (PDT) dispense

Sometimes those standard plastic tips just aren’t good enough for your automated sample preparation needs. In that case, you can switch it up to use PDTs, which are more accurate and precise for higher viscosity solutions. The tool can dispense low volumes (10 – 1000 µL) or large volumes (100 µL – 10 mL) and are compatible with multiple PDT vendors. If you have a balance on your configured system, the tool can also monitor the dispense gravimetrically.

Junior

Junior automates all your back-and-forth, over and over again, hands-on work. Explore more reaction and formulation conditions, prep samples, or hand off any other tasks you think would be better performed if you’re not the one doing it.

Big Kahuna

Big Kahuna gives you automated, high-throughput, end-to-end solutions for biologics, gene therapy vectors, small molecules, polymers and catalysts. It’s completely configurable and helps you save money and time while getting more work done.

FAQs

Want more info?

Every lab has different bottlenecks and challenges. We’re all about partnering with you to build the bespoke solution that lets you do science faster and better. Have questions or can’t wait to speak with our expert team to find out what might be possible?